From alert to action: How COREbeat saved Tharsis Mining from a critical fault

From alert to action:

How COREbeat saved Tharsis Mining from a critical fault

By Eleni Natsi & Vasilis Sagiannos (CORE Innovation Group)

In mining, every detail counts. A small oversight can ripple into costly disruptions. That’s why Tharsis Mining, a leading mining company specialising in exploration, extraction, and metallurgical research, has embraced COREbeat, a cutting-edge predictive maintenance platform.

Developed by CORE Innovation Group, COREbeat is continuously enhanced through real-world pilot projects and experimental deployments led by the CORE Innovation Centre (CORE IC) within European research projects such as MASTERMINE.

The MASTERMINE project incorporates COREbeat via the AUTOMINE module, boosting operational autonomy with Smart Predictive Maintenance (Smart PdM). The platform has already been deployed in mines across Greece, Spain, Finland, and South Africa.

COREbeat isn’t just a tool - it’s a vigilant partner, constantly ‘listening’, learning, and alerting the operational teams before problems grow. This is the story of how COREbeat’s insights turned a potential setback into a success for Tharsis Mining.

The Story of the LQ50 Fan

In June 2025, COREbeat raised an alert about the LQ50 fan in Tharsis Mining’s analytical, metallurgical, and R&D laboratory. A site check revealed that a loose mechanical hook had displaced the filter. The issue was fixed, and the alert cleared. Yet, less than a day later, COREbeat reported the same problem again. A closer look this time showed the real cause: the hook itself was faulty and unable to hold the filter securely. Once replaced, the issue was fully resolved.

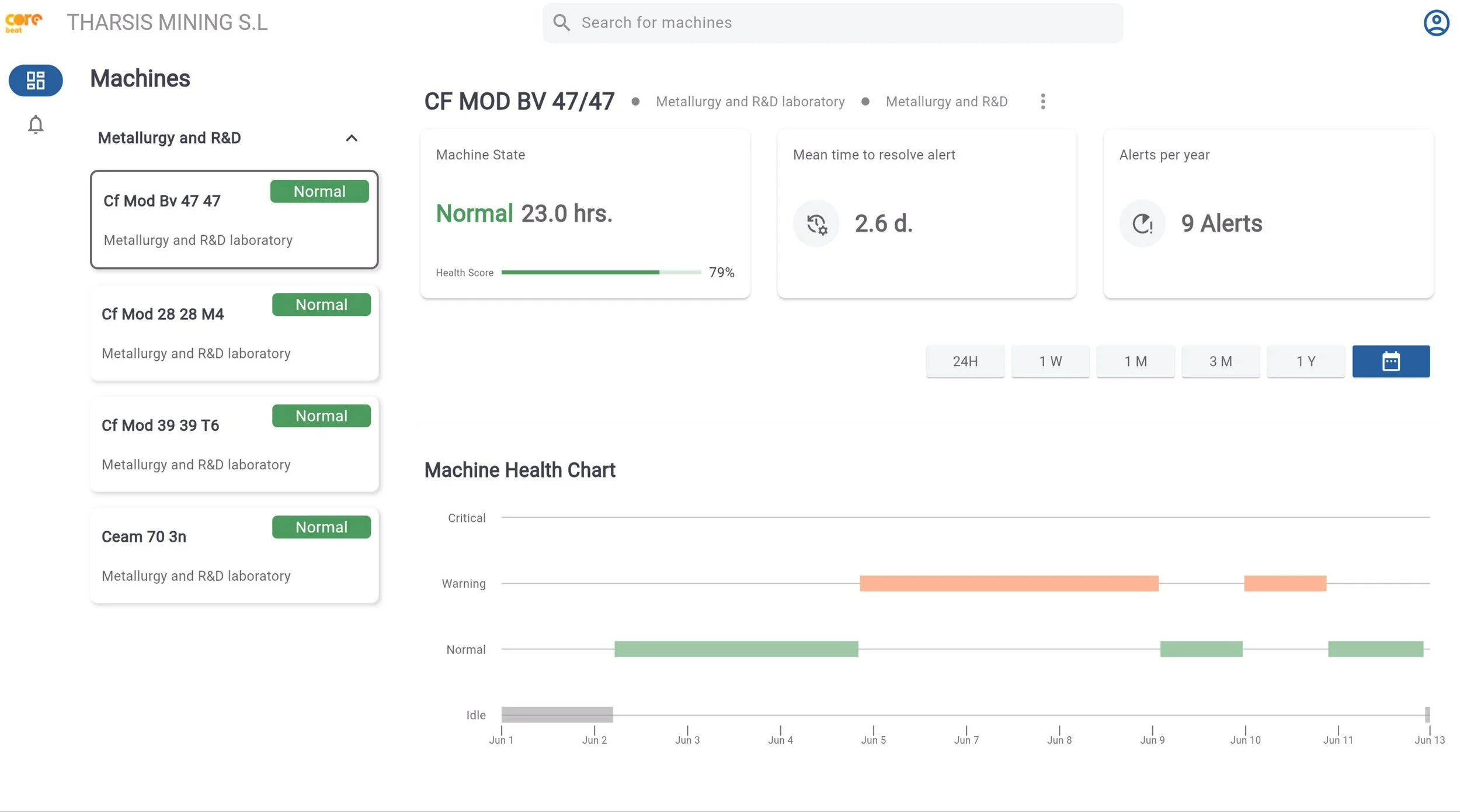

COREbeat’s dashboard in action - from the first alert to the final resolution

Why a small fault could have become a big problem

At first glance, a defective hook may sound minor. But the implications were far from small. These fans are used to supply clean air to the laboratory and extract contaminated air from it. The LQ50 provides clean air to the laboratory's analysis, drying, and office rooms. The filter’s displacement disrupted airflow, put extra load on the motor, raised vibration levels, and risked causing premature wear to key components, like bearings and couplings. Left unnoticed, it could have reduced the ventilation system efficiency, undermined the system’s reliability, and shortened the life of the equipment. Thanks to COREbeat’s persistence, the fault was found and permanently corrected before it had the chance to spiral into something larger.

COREbeat installation on the LQ50 fan

Our Tharsis Mining laboratory is equipped with an atmospheric air supply and extraction ventilation system with vibration and temperature sensors on the motors, all monitored through the COREbeat control platform. This tool enables us to track equipment status daily and take predictive action.

Some time ago, the alarm alerted us to a motor overload. Through analysis and joint review with my team, we identified that the issue stemmed from the filter’s metal hooks. We acted immediately, implemented the necessary improvements, and successfully optimised the fan’s performance, avoiding a major shutdown that would have resulted in additional maintenance costs and downtime.

This experience demonstrates the value of continuous monitoring, the use of advanced control technologies such as COREbeat, and above all, the importance of teamwork and preventive maintenance to extend the useful life of equipment and ensure the safety of our operations.

—Tamara Martínez-Santos Manjavacas, R&D Engineer at Tharsis Mining.

Technology and expertise working together

This case shows how technology and expertise can work hand in hand. COREbeat continuously monitored vibration and temperature data, while Tharsis Mining’s engineers responded quickly with their on-the-ground knowledge. The combination meant that laboratory operations - where precision is everything - were kept secure.

These operations are vital: carrying out analysis, characterisation and experimentation activities aimed at analysing samples from internal exploration and research drilling, as well as conducting metallurgical tests for the beneficiation and recovery of metals contained in different mineral resources, like gold, cobalt and copper.

More specifically, regular tasks include:

Sample preparation

Design and execution of mining and metallurgical tests.

Validation and adjustment of methodologies to ensure reproducible and reliable results.