Smart mining in action: Advancing geotechnical monitoring and digital twins

By SYSTRA SUBTERRA

The MASTERMINE project continues to advance in the implementation of innovative technologies to improve the sustainability and efficiency of mining operations in Europe. This summary highlights the progress made by SYSTRA Subterra, focusing on geotechnical monitoring in mines and the development of 3D models for geotechnical digital twins.

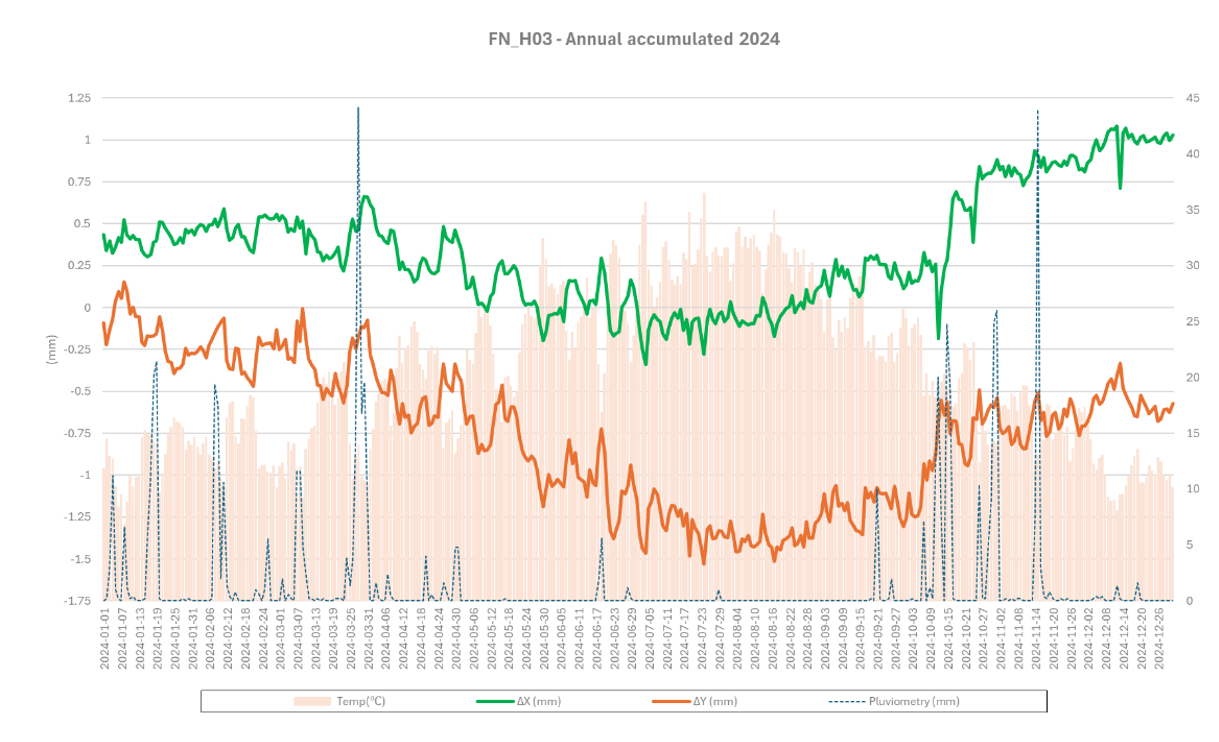

In the geotechnical monitoring task of the Tharsis mine, for each of the four sensors installed, a comprehensive graph has been generated for each year they have been operational. The displacement data has been systematically collected from late 2023 to the present day, with ongoing recordings. Upon thorough analysis, the subsequent graph is produced, illustrating the pluviometry data gathered by the meteorological station closest to the mine, alongside the historical temperature data recorded by the sensors themselves. Below is the graph for sensor number 3, showcasing the data recorded for the year 2024. In addition to displaying the longitudinal and transverse displacements recorded throughout the year, on the x-axis and y-axis. The graph clearly highlights the rainiest periods, which align with the typical climate patterns of the province, with significant water accumulations observed during the spring and autumn seasons.

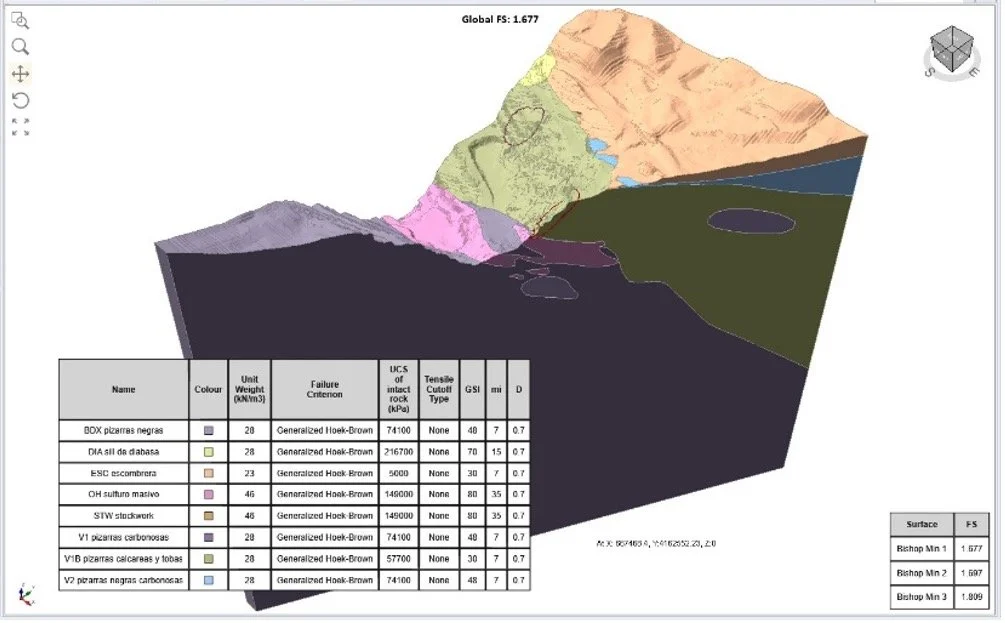

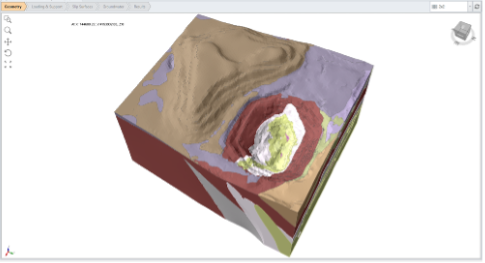

The development of three-dimensional models is an essential part of geotechnical analysis. These geological models, created from data collected from the mines, allow us a detailed understanding of geological structures, facilitating analysis and simulation within digital twins (DT).

These models, shown in the following figures, illustrate the different geological bodies that constitute the mines. These geometries must be considered with special attention when integrating them into the modelling software for further processing and analysis.

The 3D model of Tharsis mine allows the visualization of the geological features of this area, providing a solid basis for stability simulations and mining design.

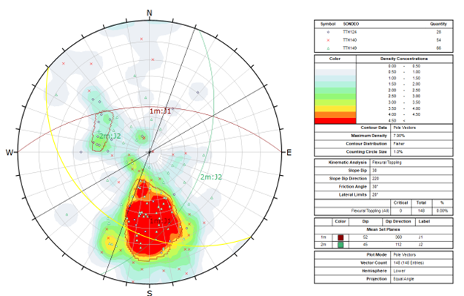

The discontinuities and joint families affecting the unstable area of the study have been identified by the use of Rocscience's Dips software and the database of drillings carried out in the area, and after a detailed study process.

Structural analysis with Dips | Analyze orientation-based geological data:

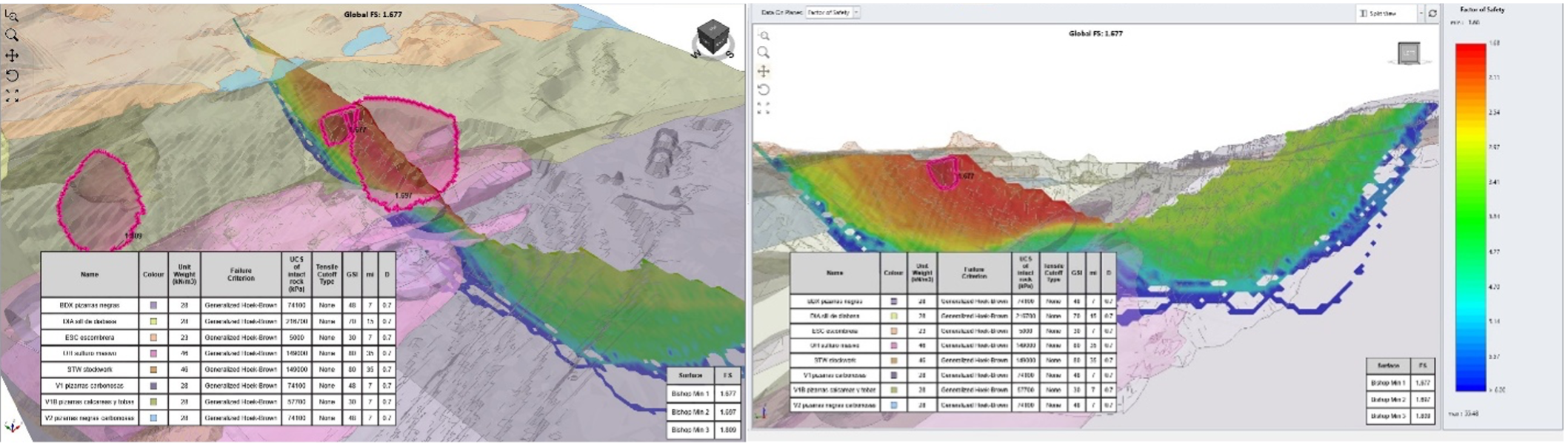

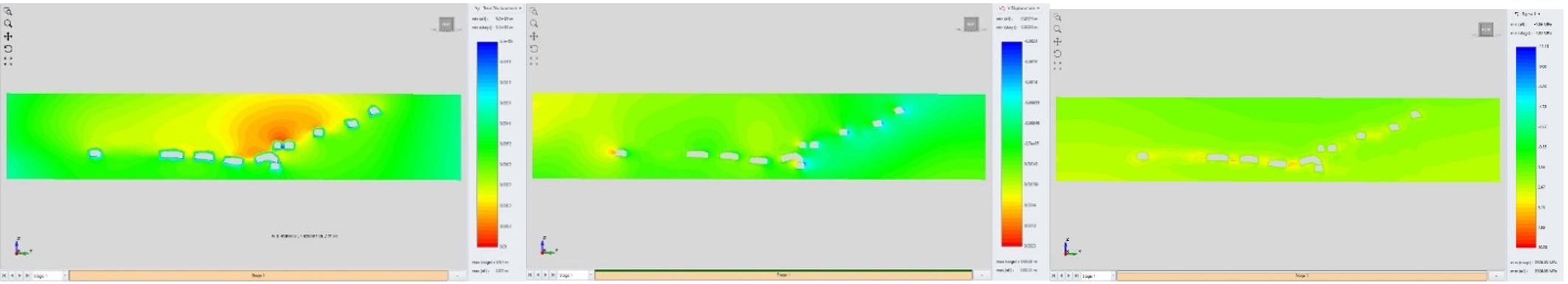

After proceeding with the structural analysis and obtaining previously the geological bodies as volumes in three dimensions, we proceeded to the analysis of the slope stability in the mine with Slide3, for which several figures are shown below. Within the software, in order to obtain the safety factor, we will have previously defined the characteristics of the materials and the failure method.

Captures of the three-dimensional model made in Slide3 | 3D Slope Stability Analysis Software:

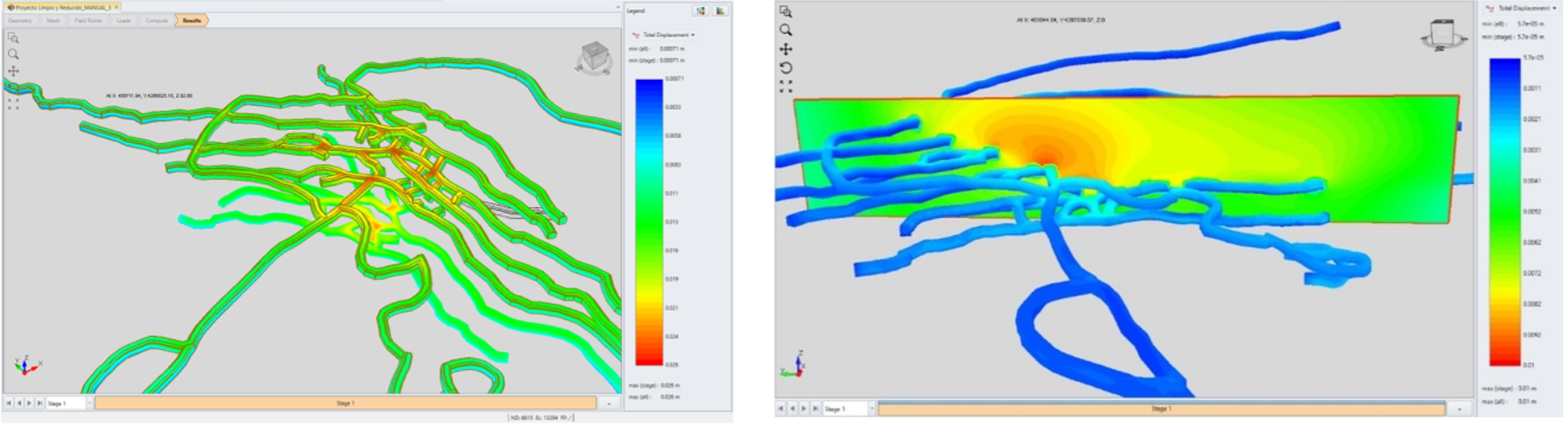

At the TernaMag test mine, progress has been made with the geometries of the galleries. The creation of an accurate point cloud has enabled the integration of the location of geotechnical monitoring sensors with the underground gallery network, providing a detailed and complete view of the mining environment. Testing has started with the specialized underground mining software, introducing the mine galleries and the point cloud as input.

Captures of EX3 | Excavation Software For Mining, 3D Stress Analysis:

Total displacement

Stresses and displacements (cross-section plane)

At Los Frailes mine, the same procedure has been followed as at Tharsis mine. The geological bodies and their properties have been incorporated into the Slide3 software and tests are being carried out on the factor of safety obtained on the unstable slope. The following figures show the model in three dimensions.

Captures of the three-dimensional model made in Slide3 | 3D Slope Stability Analysis Software: